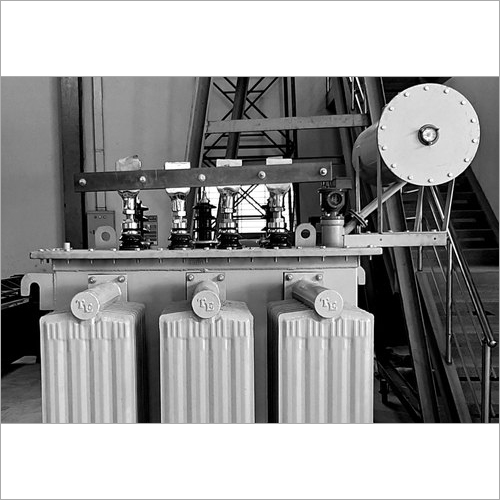

Extra Rippled Transformer Radiator

Product Details:

- Material Cold Rolled Steel / Mild Steel

- Water Content Within 250 PPM

- Central Distance 500 mm to 4000 mm (customizable)

- Working Pressure Up to 1.5 kg/cm

- Rough Weight Approx. 30-180 kg (depending on size)

- Thermal Pressure Up to 2.5 kg/cm

- Dimension (L*W*H) Length: 500-4000mm, Width: 300-350mm, Height: 500-1600mm

- Click to View more

Extra Rippled Transformer Radiator Price And Quantity

- 20000 INR/Ton

- 25 Ton

Extra Rippled Transformer Radiator Product Specifications

- High surface area for increased cooling efficiency, corrosion resistance, durable structure, easy installation

- Length: 500-4000mm, Width: 300-350mm, Height: 500-1600mm

- Up to 1.5 kg/cm

- Up to 2.5 kg/cm

- Approx. 30-180 kg (depending on size)

- Cold Rolled Steel / Mild Steel

- 500 mm to 4000 mm (customizable)

- Within 250 PPM

Extra Rippled Transformer Radiator Trade Information

- 100 Ton Per Month

- 15 Days

Product Description

The Offered Extra Rippled Transformer Radiator accelerates the cooling rate of transformer. Thus, it plays a vital role in increasing loading capacity of an electrical transformer. This is basic function of radiator of an electrical power transformer. The radiator of transformer accelerates the cooling rate of transformer. Thus, it plays a vital role in increasing loading capacity of an electrical transformer. This is basic function of radiator of a power transformer. It is designed with extra care in compliance with the international quality standards. The offered Extra Rippled Transformer Radiator is very efficient and useful.

Specification

|

Certification |

TUV Stamp |

|

Coolant Used |

Synthetic Liquid |

|

Type |

Customised |

|

Tube Type |

Seamed |

Enhanced Cooling for Transformers

The extra rippled design maximizes the radiators surface area, ensuring more effective heat dissipation from transformer oil. This innovative structure delivers increased cooling efficiency, which is vital for transformer reliability and operational lifespan in various environmental conditions.

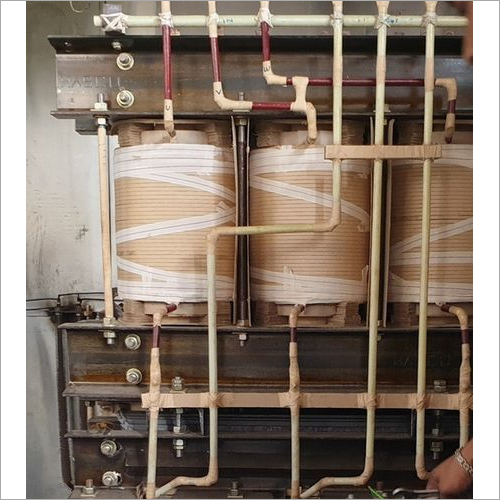

Superior Build and Customization

Manufactured from cold rolled or mild steel, each radiator undergoes advanced processes such as hot dip galvanization or epoxy painting. Customization options include thickness, number of panels, connection type, and dimensions, allowing integration with diverse transformer configurations.

Precision Engineering and Quality Assurance

Every radiator is 100% pressure tested before shipment, guaranteeing leak-free and dependable performance. Engineered to comply with industry benchmarks like IS 3347 and IEC, the product promises unmatched durability, safety, and longevity in power distribution setups.

FAQs of Extra Rippled Transformer Radiator:

Q: How do extra rippled tubes in the radiator improve cooling efficiency?

A: The extra rippled tubes significantly increase the radiators surface area, enabling more effective heat dissipation from the transformer oil. This design facilitates faster cooling, which helps maintain optimal transformer performance and reduces the risk of overheating.Q: What customization options are available for these transformer radiators?

A: Our Extra Rippled Transformer Radiators can be customized in thickness (1.2 mm to 1.5 mm), number of panels, central distance (500 mm to 4000 mm), connection type (flanged or welded), and color, ensuring compatibility with diverse transformer requirements.Q: When should I choose a hot dip galvanized versus an epoxy painted finish?

A: Hot dip galvanized finishes are ideal for environments prone to corrosion or moisture, offering exceptional rust protection. Epoxy painted finishes provide a smooth, aesthetically pleasing surface with excellent chemical resistance, suitable for controlled indoor installations.Q: Where are these radiators commonly used?

A: These radiators are typically used in power and distribution transformers across electrical substations, utility networks, industrial plants, and infrastructure projects, especially where high-efficiency cooling and durability are critical.Q: What is the process for ensuring quality and reliability of the radiators?

A: Every unit undergoes stringent 100% pressure testing prior to dispatch. Rigorous adherence to IS 3347 and IEC manufacturing standards ensures the highest levels of safety, performance, and product integrity.Q: How do I determine the right size and specifications for my transformer?

A: Our team will work with your technical requirements, such as the transformers size, cooling needs, installation environment, and operational pressures, to recommend the ideal radiator configuration and dimensions.Q: What are the main benefits of using the Extra Rippled Transformer Radiator?

A: Key benefits include enhanced cooling efficiency, long-term corrosion resistance through superior surface treatments, robust construction, easy installation, full compliance with industry standards, and customization for specific transformer applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+