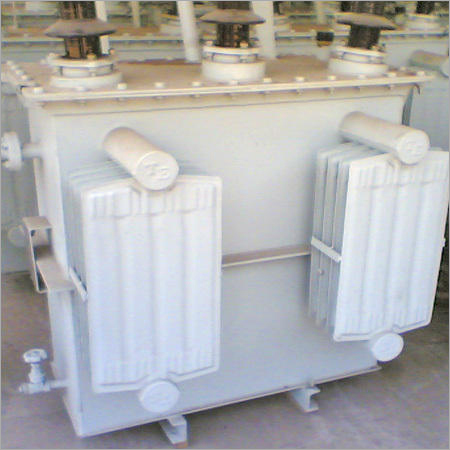

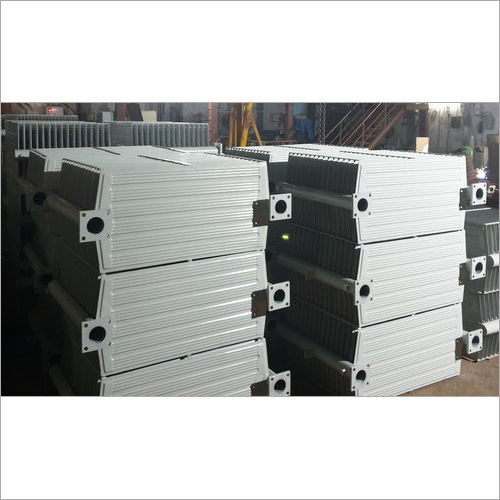

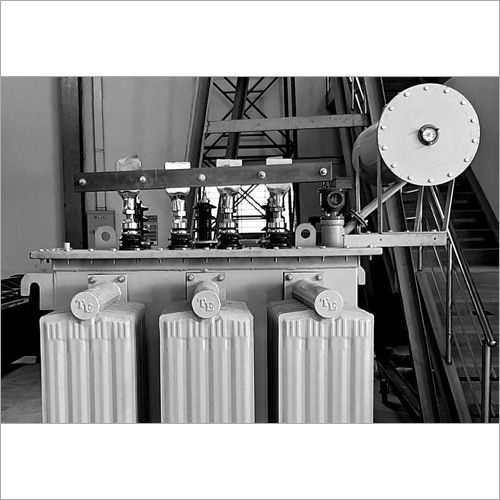

Tepl Direct Weldable Type Pressed Steel Radiators

Product Details:

- Material High-grade pressed steel

- Water Content 1.5 Litres per section

- Central Distance 500 mm

- Working Pressure Maximum 10 kg/cm

- Rough Weight Approximately 3.5 kg per section

- Thermal Pressure maximum test pressure of 13 kg/cm

- Dimension (L*W*H) Section size - 62 mm x 100 mm x 580 mm

- Click to View more

Tepl Direct Weldable Type Pressed Steel Radiators Price And Quantity

- 100 Ton

- 20000 INR/Ton

Tepl Direct Weldable Type Pressed Steel Radiators Product Specifications

- 500 mm

- High-grade pressed steel

- Direct weldable, high heat output, corrosion resistant, robust construction

- maximum test pressure of 13 kg/cm

- Section size - 62 mm x 100 mm x 580 mm

- Maximum 10 kg/cm

- Approximately 3.5 kg per section

- 1.5 Litres per section

Tepl Direct Weldable Type Pressed Steel Radiators Trade Information

- 15 Ton Per Month

- 7 Days

Product Description

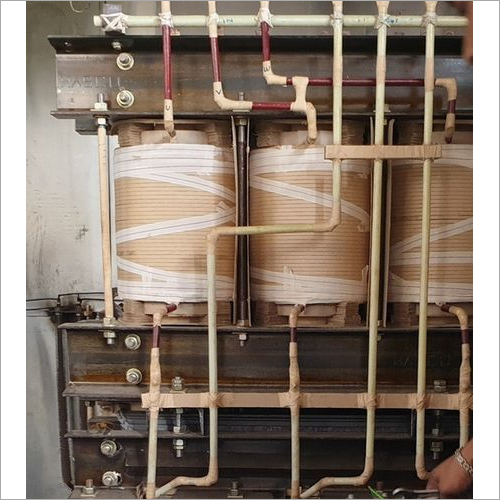

Tepl direct weldable type pressed steel radiators are built from steel that has been pressed into shape. These are frequently utilised in industrial environments, as well as radiators for cars and trucks. Our offerings are renowned for their robustness, long lifespan, and quick heat dissipation. The said products are robust in construction, easy to install and anti-corrosive in nature. Tepl direct weldable type pressed steel radiators keep warm for a long period even after being turned off because they are good heat conductors. They can also be fashioned into unusual shapes to create stunning heating statement pieces.

Specification

| Certification | TUV Stamp |

| Brand Name | TEPL |

| Tube Type | Seamed |

Exceptional Heat Performance and Versatility

Delivering up to 120 Kcal/hr per section at a 60C temperature difference, these radiators provide reliable warmth for oil or water-based systems. Their single-column structure enhances heat exchange while ensuring compact installation, serving both industrial and residential purposes.

Built to Last: Advanced Protection and Robust Construction

Each radiator features a high-grade pressed steel core, coated with polyester powder and treated against corrosion. This guarantees long-lasting performance, even indoors in environments prone to moisture or temperature fluctuations, making it an excellent choice for export, commercial, or domestic applications.

Flexible Installations with Direct Weldable Advantage

The unique direct weldable design allows secure connection to pipelines, drastically reducing installation time and minimizing leakage risks. Standard BSP 1 pipe threads and a central distance of 500 mm ensure easy integration into new or existing heating setups, maximizing efficiency in diverse projects.

FAQs of Tepl Direct Weldable Type Pressed Steel Radiators:

Q: How is the Tepl Direct Weldable Radiator installed?

A: This radiator is designed for direct welding to pipelines, allowing for a secure and seamless connection. It uses standard BSP 1 pipe threads, making it compatible with most plumbing systems. Professional welding is recommended to ensure optimal safety and performance.Q: What are the main benefits of using this pressed steel radiator?

A: The core advantages include high heat output, direct-weld installation for leak prevention, robust build quality from high-grade pressed steel, excellent corrosion resistance, and versatile application for both oil-filled and water heating systems. It is also available in custom colours.Q: When is this radiator suitable for use?

A: It is suitable for deployment in heating systems requiring rapid heat transfer and resilience, such as industrial plants, commercial buildings, and residences using oil or water-based central heatingwith a temperature capability up to 95C and pressure tolerance up to 10 kg/cm.Q: Where can these radiators be applied most effectively?

A: They are highly effective in locations demanding robust construction and reliable heat output, ranging from industrial and commercial facilities to residential heating networks. Their corrosion resistance makes them especially suitable for moist or variable climate environments.Q: What is the process for customizing the radiators colour?

A: While standard units are finished in white, customers can request custom colours during the ordering process. The radiators are coated with a durable polyester powder finish, ensuring the selected colour remains vivid and resists wear over time.Q: How much water does each section contain, and why is this important?

A: Each section holds 1.5 litres of water, which enables efficient heat transfer and supports consistent heating without frequent maintenance. This design also optimizes the radiators response time, allowing for fast warming cycles.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free