Onload Tap Changer (OLTC)

Product Details:

- Low Voltage 0.4-1.1 kV

- Standard IS 2026 / IEC 60214

- Dimension (L*W*H) Customvaries per installation

- Capacity Up to 4000 kVA

- Voltage Booster Type Linear booster

- Coil Material Electrolytic Copper

- Cooling Type ONAN (Oil Natural Air Natural)

- Click to View more

Onload Tap Changer (OLTC) Price And Quantity

- 400000-600000 INR/Piece

- 4 Piece

Onload Tap Changer (OLTC) Product Specifications

- 25C to +105C

- 11 kV / 22 kV / 33 kV (custom options available)

- 11-33 kV

- >98%

- Reduced according to transformer rating

- Custom as per transformer design

- 50 Hz

- Linear booster

- Electrolytic Copper

- Depending on transformer rating (approx. 150-400 kg)

- ONAN (Oil Natural Air Natural)

- Onload Tap Changer (OLTC)

- Customvaries per installation

- Voltage regulation in transformers

- Mild Steel and Copper

- Up to 4000 kVA

- Toroidal

- Three Phase

- 0.4-1.1 kV

- IS 2026 / IEC 60214

- Up to 4000 kVA

- Automatic voltage adjustment

Onload Tap Changer (OLTC) Trade Information

- kolkata

- 100 Piece Per Month

- 15 Days

- No

- standard

- Asia, Middle East, Africa

- All India

- ISO 9001:2015

Product Description

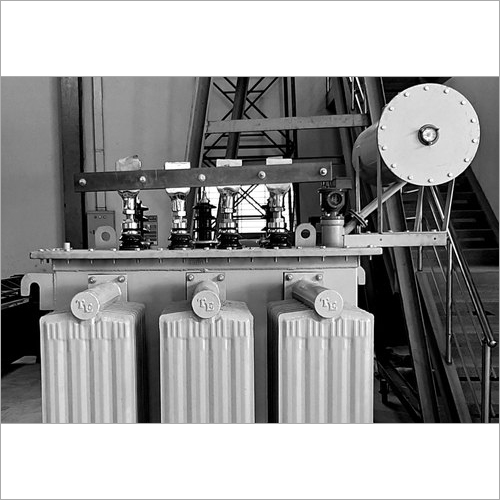

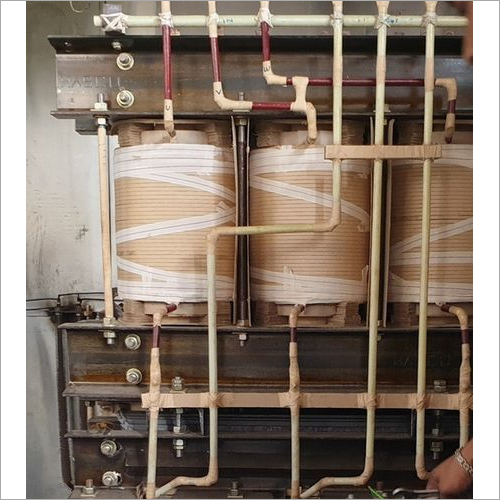

Notable for its compact shape, this Onload Tap Changer deserves praise for its high output and long lasting quality. Core of this device has been developed from well chosen raw material to avoid aging and to enhance permeability level. Surface of this core is laminated with silicon steel to prolong its service life. Insulation oil used by this machine conforms to IEC norms. As part of its safety features, this Onload Tap Changer has pressure relief valve to adjust internal pressure of its tank. This system also comprises of other accessories like silicon steel plate, oil level gauge, cooling fan, iron core and copper foil. Prolong service life, sturdy construction and ease of maintenance are some of its main features.

Product Specification of Onload Tap Changer

|

Phase |

Three Phase |

|

Brand |

OLTC |

|

Packaging Type |

Box |

|

Power/Voltage |

320V to 420V |

|

Current Rating |

120A |

Advanced Design & Construction

This OLTC is crafted from high-quality materials including mild steel and electrolytic copper. Its flange or side mounting ensures compatibility with diverse transformer configurations, while robust oil-immersed insulation meets IS/IEC standards. The coil structure is toroidal, providing efficient automatic voltage adjustment for three-phase transformers.

Reliable Performance & Operation

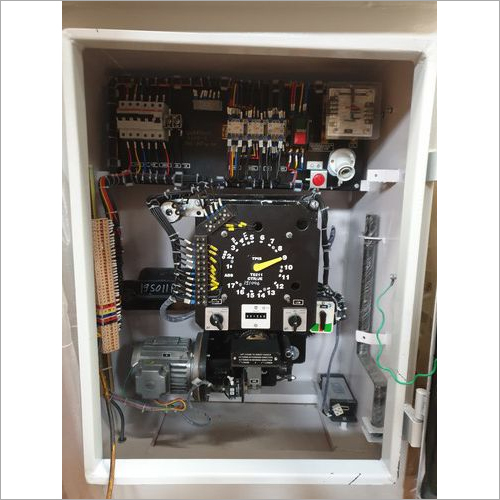

Equipped with high-grade silver alloy contacts and transition resistors, the tap changer enables safe, efficient voltage regulation. The motor-driven mechanism, with manual override, supports both remote and local control panel operations. The device ensures optimal performance under ambient humidity up to 95% RH and temperature ranging from 25C to +105C.

Safety, Efficiency & Longevity

Built-in interlocks and advanced protection features safeguard both the OLTC and transformer. With efficiency exceeding 98%, minimized load loss, and maintenance-friendly design, the OLTC extends transformer service life beyond 25 years. Customizable tap steps (17, 21, 33), and voltage ratings (11/22/33 kV) address varied application needs across India and global markets.

FAQs of Onload Tap Changer (OLTC):

Q: How does the OLTC facilitate tap changing in transformers?

A: The OLTC performs tap changes using a motor-operated mechanism, allowing seamless adjustment of transformer voltage under load. Manual override ensures operation in case of motor failure, with position indications available both manually and digitally for precise monitoring.Q: What benefits does oil-immersed operation provide for this OLTC?

A: Oil-immersed design enhances insulation, cools internal components, and maintains stable operation in demanding environments. It supports a wide ambient humidity range (up to 95% RH), thereby prolonging product service life and reliability.Q: Where is the OLTC mounted on a transformer, and what are the available options?

A: The OLTC can be flange mounted or side mounted, depending on transformer design and user requirements. This flexibility ensures easy integration and optimal space utilization for new installations or retrofit applications.Q: When is remote and local control of the tap changer useful?

A: Remote control permits operators to regulate transformer voltage from a distance, enhancing operational safety and convenience. Local control remains essential for on-site maintenance checks or emergency manual operation, ensuring reliability in all scenarios.Q: What makes the OLTC low-maintenance and easy to inspect?

A: The OLTC uses high-grade silver alloy contacts and adheres to IS/IEC standards, offering durability and reducing wear. Its user-friendly construction allows straightforward inspection and servicing, minimizing downtime and operational costs.Q: How does the transition resistor improve safety during tap changing?

A: A fitted transition resistor limits the current during tap transitions, preventing electrical surges and protecting both the OLTC and transformer windings. This ensures smooth operation and upholds equipment safety.Q: What is the typical service life of the OLTC, and under what conditions?

A: The OLTC is engineered for a service life exceeding 25 years, functioning efficiently within operating temperatures of 25C to +105C and high ambient humidity, provided it is installed and maintained according to manufacturer guidelines.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free