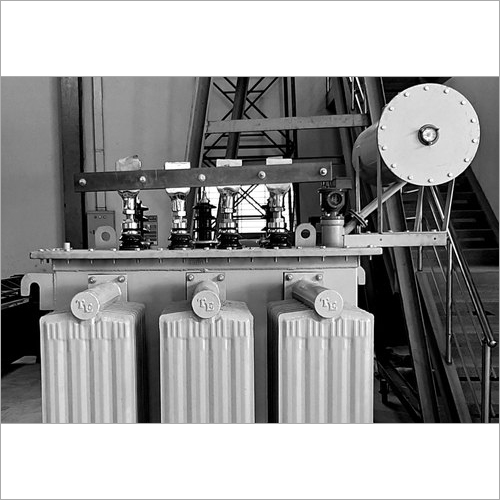

Heavy Duty Transformer Radiator

5000-100000 INR

Product Details:

- Material Pressed Steel (finely finished, corrosion-resistant)

- Water Content 2.5 liters per element (Average)

- Central Distance 1000 mm (customizable as per design)

- Working Pressure 1.5 bar

- Rough Weight 15 kg per element

- Thermal Pressure Up to 120C

- Dimension (L*W*H) 1000 mm x 310 mm x 70 mm (Standard size; customizable on request)

- Click to View more

X

Heavy Duty Transformer Radiator Price And Quantity

- 5000-100000 INR

- 100 Ton

Heavy Duty Transformer Radiator Product Specifications

- Pressed Steel (finely finished, corrosion-resistant)

- 1000 mm (customizable as per design)

- High efficiency heat dissipation, robust structure, quick installation, suitable for heavy-duty applications

- 1000 mm x 310 mm x 70 mm (Standard size; customizable on request)

- 2.5 liters per element (Average)

- 15 kg per element

- Up to 120C

- 1.5 bar

Heavy Duty Transformer Radiator Trade Information

- kolkata

- 100 Ton Per Month

- 15 Days

- No

- standard

- All India

- iso 9001:2015

Product Description

Product Details:

|

Minimum Order Quantity |

100 Piece |

|

Certification |

TUV Stamp |

|

Type |

Customised |

|

Tube Type |

Seamed |

|

Coolant Used |

Synthetic Liquid |

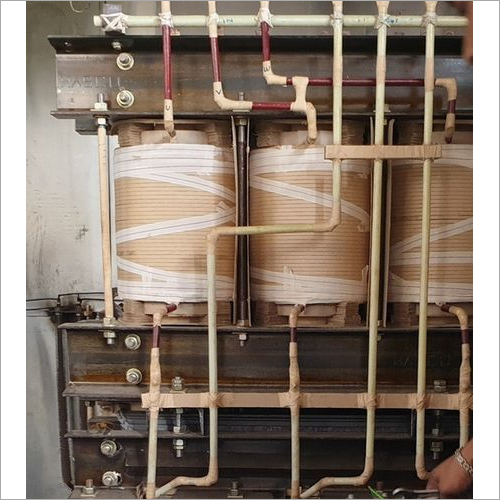

The Heavy Duty Transformer Radiators are highly efficient in nature. We are providing this Electrical Transformer Radiators in various dimensions and specifications. Electrical Transformer Radiators is extensively used in industrial applications. Moreover, we deliver this Electrical Transformer Radiators to various places in speculative time limits.

Features:

- Quality assured

- Easy to use

- Longer functional life

Superior Surface Coating for Longevity

The transformer radiator features an epoxy/polyester powder-coated surface, imparting exceptional resistance against corrosion and extending operational life. This treatment ensures efficient heat dissipation and structural integrity even in harsh environments, making it suitable for heavy-duty transformer operations in varied conditions.

Customizable Design & International Compliance

Engineered to comply with IS 3347 and available for customization to meet international standards, these radiators can be tailored in central distance, dimensions, and mounting orientations. Welded flanges and sturdy construction allow for seamless integration into various transformer designs, offering flexibility and reliability worldwide.

FAQs of Heavy Duty Transformer Radiator:

Q: How does the epoxy/polyester powder coating enhance corrosion resistance for the transformer radiator?

A: The epoxy/polyester powder coating forms a protective barrier over the pressed steel surface, preventing moisture, chemicals, and environmental agents from causing corrosion. This results in prolonged radiator lifespan and reduced maintenance requirements even in challenging operational environments.Q: What is the process for leak testing these heavy duty transformer radiators?

A: Every radiator is subjected to a 100% hydrostatic leak test to verify its sealing integrity and working pressure. This rigorous testing ensures reliable performance without fluid leakage under standard operating pressures up to 1.5 bar.Q: When should I consider customizing the central distance or dimensions of the radiator?

A: Customization should be considered when your transformer design or installation space warrants specific sizing or spacing requirements. The standard central distance is 1000 mm, but this can be altered to fit unique transformer specifications upon request.Q: Where are these radiators suitable for use?

A: These heavy duty radiators are ideal for liquid or oil-immersed power and distribution transformers in power plants, substations, industrial facilities, or any environment requiring robust heat dissipation and corrosion resistance.Q: What benefits does the corrugated or flat fin section offer for heat dissipation?

A: Corrugated and flat fin sections increase the radiators surface area available for heat transfer, thereby improving the overall efficiency of heat dissipation. This protects transformer components from thermal stress and extends service life.Q: How are the radiators packed for export and transportation to ensure safety?

A: Radiators are packed on seaworthy pallets, securely wrapped with protective film to prevent damage during handling and shipping, ensuring arrival in prime condition regardless of destination.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email