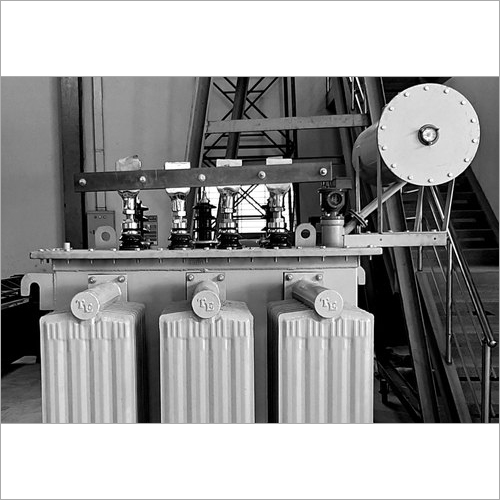

Distribution Transformer

300000-1000000 INR/Piece

Product Details:

- Rated Voltage 11 kV / 0.433 kV

- Standard IS 1180, IEC 60076

- Dimension (L*W*H) 1800 mm x 1250 mm x 1700 mm (varies by rating)

- Voltage Booster Type Tap Changer (Off Circuit Tap Links)

- Load Loss 1.9 kW (for 1000 kVA at 75C)

- Low Voltage 0.433 kV

- High Voltage Up to 11 kV

- Click to View more

X

Distribution Transformer Price And Quantity

- 10 , , Piece

- 300000-1000000 INR/Piece

Distribution Transformer Product Specifications

- 3 kVA to 2500 kVA

- 50 Hz

- Variable as per rating (commonly 11 kV/433 V)

- 11 kV / 0.433 kV

- IS 1180, IEC 60076

- ONAN (Oil Natural Air Natural)

- 1800 mm x 1250 mm x 1700 mm (varies by rating)

- 98% (Typical)

- 2 (Primary & Secondary)

- Oil Cooled Distribution Transformer

- Three Phase

- Electrolytic Copper

- Tap Changer (Off Circuit Tap Links)

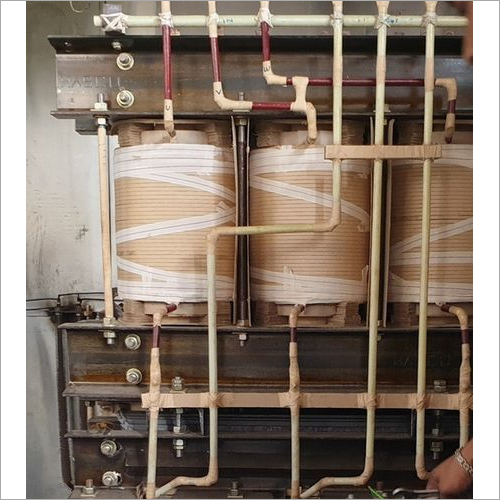

- Toroidal/Layer Wound

- Electrical Power Distribution

- 1.9 kW (for 1000 kVA at 75C)

- -25C to +45C

- 0.433 kV

- Up to 2500 kVA

- Copper/Aluminum Winding with CRGO Silicon Steel Core

- Up to 11 kV

- Approx. 1850 kg (for 1000 kVA rating)

Distribution Transformer Trade Information

- kolkata

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- 10 , , Piece Per Day

- 30 Days

- No

- standard

- All India

- ISO 9001:2015

Product Description

This high performance Distribution Transformer is known for its 50-60 Hz rated frequency, maximum 11 kV voltage level. Back up fuse and double sensitivity fuse are used to install and connect this device with power supplying unit. Plug in type insulated cable joint of this Distribution Transformer is simple to handle and operate. This energy efficient system deserves praise for its low noise operation, low loss and small volume. Sealed housing of this product is totally protected against moisture, dust and condensation. Spray painted surface of its housing can efficiently resist rust formation. Steel sheet made oil tank of this product is carefully welded to avoid leakage. Compact in shape, this transformer system has gone through a number of testing procedures to prove its flawlessness.

Advanced Electrical Distribution Solution

This distribution transformer is specifically designed for safe and reliable electrical power distribution across varied environments. It combines high-grade CRGO silicon steel core, electrolytic copper/aluminum windings, and Class A or F insulation to ensure exceptional performance, even under demanding conditions. Offering up to 2500 kVA power capacity, the unit guarantees consistent output and robust efficiency.

Durable Engineering & Longevity

Constructed to endure harsh environmental conditions, this transformer features IP 23 protection, corrosion-resistant epoxy or powder-coated finish, and a Buchholz relay system for enhanced safety. The device ensures more than 25 years of service life when used under normal operations and is engineered for noise levels below 55 dB, ensuring smooth integration into urban and rural settings alike.

Comprehensive Features & Standards Compliance

Equipped with vital accessoriesincluding oil level gauge, temperature indicator, and pressure relief devicethis transformer meets IS 1180 and IEC 60076 international standards. Its versatile mounting options and mineral oil compliant with IS 335 offer flexibility and assure optimal operation for electrical power distribution requirements in India and abroad.

FAQs of Distribution Transformer:

Q: How is the insulation class (Class A or Class F) important for the transformers operation?

A: The insulation class determines the maximum temperature the transformer windings can safely handle, ensuring longevity and optimal performance. Class A and Class F insulation options provide flexibility for different operating environments, enhancing durability and heat resistance.Q: What is the function of the Dyn11 vector group in this distribution transformer?

A: The Dyn11 vector group describes the winding configuration and phase displacement between primary (delta) and secondary (star) windings. It allows for effective load balancing and reduction of harmonics, making the transformer suitable for most distribution networks.Q: When should I use pole-mounted versus pad-mounted transformers?

A: Pole-mounted transformers are ideal for overhead distribution in rural or urban areas with limited ground space. Pad-mounted units are preferable for ground installations, providing easier access for maintenance and increased safety in public spaces.Q: Where is this transformer best deployed?

A: This transformer is suitable for use in electrical distribution networks, both in industrial and commercial settings. Its robust construction, noise control, and adaptability for various mounting types make it compatible for use across city grids, industrial estates, and remote installations.Q: What process is followed for ensuring transformer protection and operational safety?

A: The transformer is equipped with protection features such as an oil level gauge, Buchholz relay, temperature indicator, and pressure relief device. These systems enable early detection of faults and safe operation, minimizing risks of damage and downtime.Q: How does using mineral oil as per IS 335 benefit the transformer?

A: Mineral oil, compliant with IS 335, provides effective cooling and insulation, reducing oxidation, extending service life, and minimizing maintenance needs. This ensures the transformer operates efficiently within the specified temperature range and environmental conditions.Q: What are the advantages of having a service life of over 25 years?

A: An extended service life translates to reduced replacement costs, lower operational downtime, and long-term reliability for electrical networks. Proper use, as per guidelines, assures continuous and efficient power distribution for decades.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email