Products

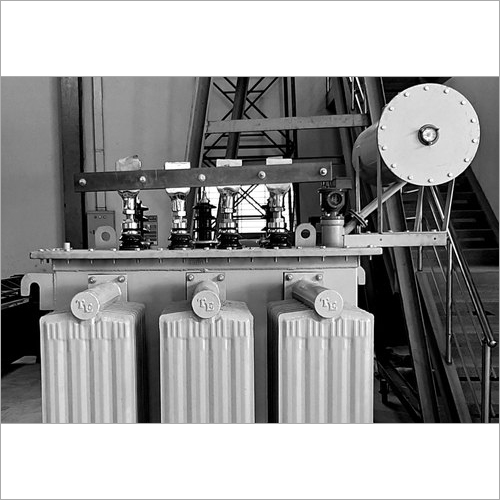

- Pressed Steel Radiators (Flange type)

- Pressed Steel Radiators (Direct weld-able type)

- Swan Neck Radiators (FR-Type Radiators with flange and upper connection depressed as per EN 50216-6:2002)

- Radiators with square flanges and elements of unequal length

- Stainless Steel Radiators (304 or 316 Grade).

(FA type Radiators with flanges and elements having different lengths. EN 50216:6-2002).

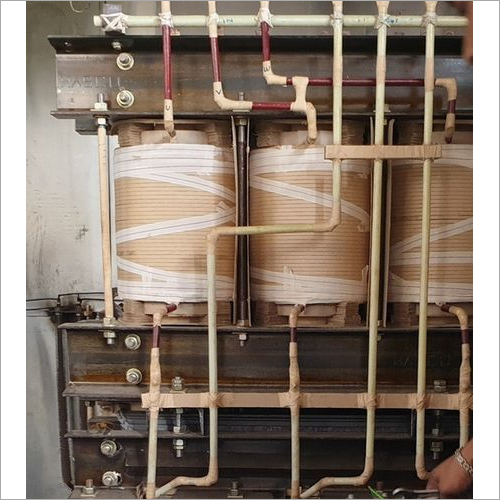

Raw Material and Process Flow

- CRCA steel strips D.D grade 2.0 mm thick for header pipes in 75 mm or 90 mm diameter as per customer requirement. Larger headers of 100 NB and 150 NB are also available as per customer requirements

- Accessories such as m.s square / round flanges, air vent, drain plug, lifting hooks, bracing straps are standard but can be supplied as per customer specific requirements.

Internal Surface Preparation

The

internal surface of the Radiators are cleaned in order to avoid

transformer oil contamination with oil for transformers as per to

ISO 4406 and coated (flush coating) with varnish. Internal surface

painting can also be arranged as per specific purchaser requirements.

External Surface Preparation

Finished painting

is done by enamel / epoxy paint or as per customer specification. Sand

/ quartz / grit blasting as per customer requirement. We have a surface

treatment section equipped with steel shot blasting machine and

painting system.

Tests

All

Radiators are pressure tested on individual basis for leakage proof under

water at an air pressure of 200 kPa (2kg/ cm2) for 30 minutes.

(Standard water immersing test). Compliance is checked by immersing the

Radiators in a water filled tank. Randomly selected Radiators from all

consignments goes through hot oil test. (the Radiators are filled with

transformer oil at a temperature of 600 C and kept at a pressure of

200 kPa ( 2.0394 kgf/ cm2) for 3 Hours to ensure no oil leaks.

External surfaces of the Radiators are checked for deformations.

Inspections

I. Dimension and tolerances check

II. Visual inspection for welding

III. Internal surface check for presence of any foreign bodies or contamination

IV. Paint peel off test (inspection of external paint).

Preparation for Transportation and Storage

Our

Quality Control Division carries out one final check for radiator

cleanness, foreign bodies and other contamination. The Radiators passed

trough a stringent checking system developed by our qualified engineers

and technicians.

Flanges

are covered to prevent the ingress of contamination during

transportation or storage. We take all possible measures to avoid

mechanical damages to the Radiators.

With

our radiators, we try to serve our customers to reduce their costs

through savings on fluids due to our superior heat transfer, and the

reduction of number of elements per radiators per transformer (reducing

labor, handling, etc.)

Profile

THERMOCOOL is an ISO 9001-2008 certified company established in 2003 for the manufacturing of fin type radiators for power & distribution transformers.

(FA type Radiators with flanges and elements having different lengths; EN 50216:6-2002).

Besides standard products, we also design and manufacture customized Pressed Steel Radiators, Tanks & Panels to meet clients' special requirements.

Our standard Pressed Steel Radiators, Tanks & Panels meet IEEMA (Indian Electrical Equipment Manufacturers Association) specifications and BSEN 50216 (previously DIN 42559) standard.

PRINCIPLE: Once our customer must always be our satisfied customer.

Those who trusted us with one order have remained with us ever after.

Call Me Free

Call Me Free